Disea has a complete system of quality management

Develop products based on the industrial design principles.

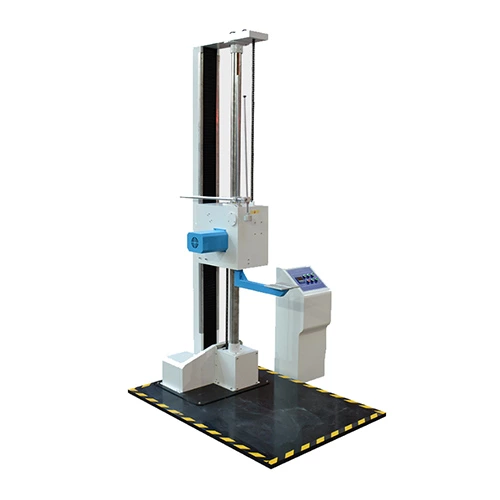

Sampling aging for small or some batches products.

OQC full inspection for small batch and mass production products.

100% aging verification for new developed products.

Industrial products can pass the industry's top 85 ℃&85%RH, 240 hour test.

Annual TFT automatic bonding yield: 99.72%.

The quality department has a well organizational structure and adheres strictly to ISO standards.

Disea has a complete system of quality management

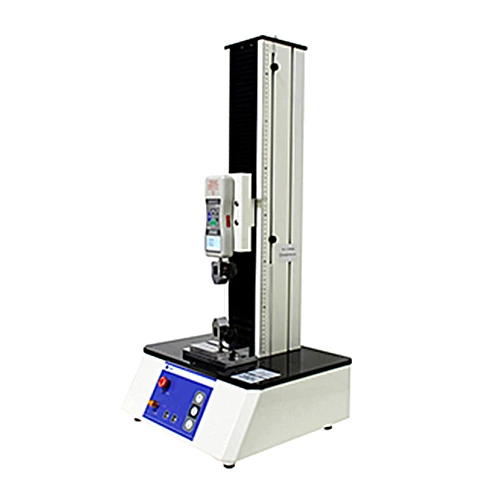

Incoming Quality Control (IQC) refers to the quality confirmation and verification of purchased raw materials, components or products...

IPQC stands for In-Process Quality Control. It refers to quality control in the input process of raw materials, production, and packaging ...

OQC stands for Outgoing Quality Control. It is responsible for checking the finished product with packaging using AQL sampling plan. QCs are supposed to pick out defective products, parts, components or material, keep them in defective piles, and send them back for rework...

Disea has obtained certifications including ISO9001: 2015 International Quality Management System, IATF16949 Global Automotive Quality Management System.

> Details...

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.