What Are the Different Structures of Capacitive Touch Screens?

Capacitive touch screens have become widely used in the industrial sector, and their touch technology continues to evolve. So, what are the mainstream structures of capacitive screens today?

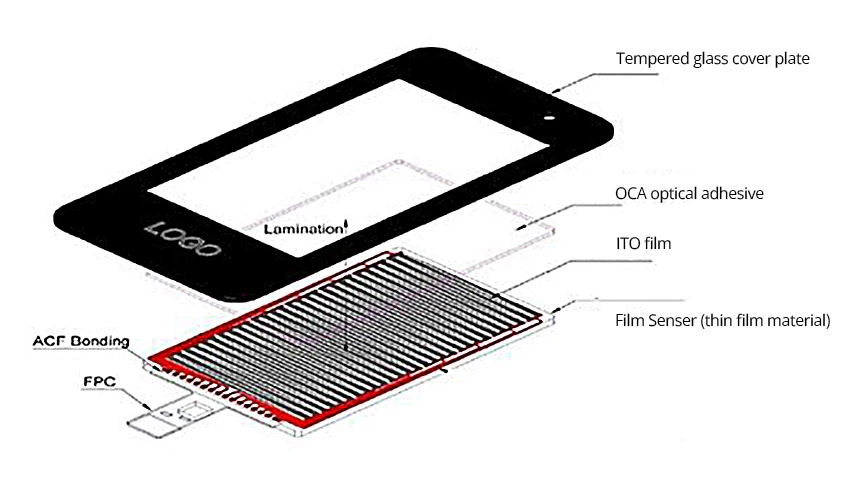

1. G+F Structure

The G+F structure features a surface layer of tempered glass followed by a film material. This consists of a glass cover + OCA (Optically Clear Adhesive) + Film Sensor. The glass cover provides protection and enhances the surface texture, typically made from high-strength, hard, and highly transparent tempered glass. The OCA is a solid optical adhesive with good stickiness and light transmission, used to bond the glass cover to the Film Sensor, which is responsible for transmitting touch signals. This structure is suitable for products under 3.5 inches and is a low-cost solution.

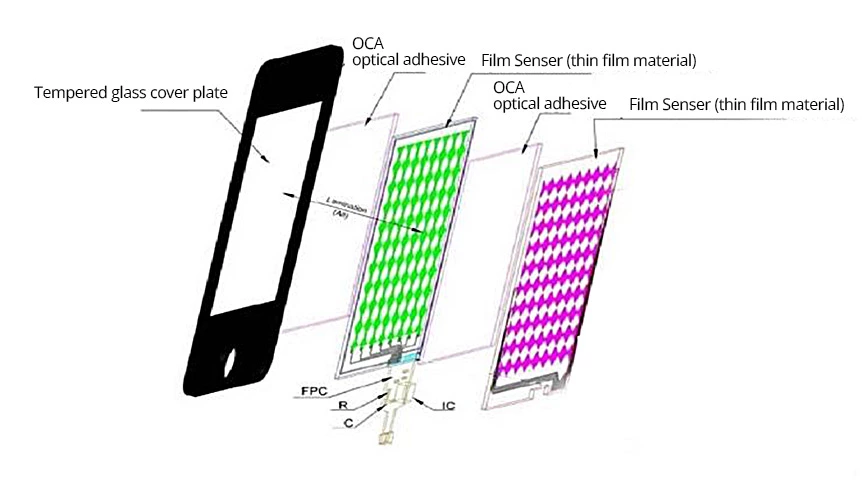

2. G+F+F Structure

The G+F+F structure also starts with a layer of tempered glass but includes two layers of film material, with the second layer being an additional Film Sensor. This structure allows for multi-touch capabilities, a thinner screen, and higher costs compared to the G+F structure.

3. G+G Structure

The G+G structure, meaning Glass+Glass, includes a tempered glass surface layer and a glass material sensor. The key difference from the G+F structure is the use of glass for the sensor. The G+G capacitive screen is characterized by its hardness, scratch resistance, corrosion resistance, high light transmission, smooth touch, and reliability. The tempered glass surface cover is extremely hard, with a hardness rating of over 8H, offering excellent scratch prevention.

4. G+P Structure

The G+P structure consists of a tempered glass surface layer and a PC (polycarbonate) touch layer. The G+P structure is cost-effective and simple to manufacture. However, it has drawbacks such as poor wear resistance, low corrosion resistance, lower light transmission, slower response time, and reduced reliability.

These are the most common capacitive touch screen structures currently on the market. Each structure has its advantages and disadvantages, so users should choose the capacitive screen product that best suits their cost requirements and application field.