The composition, working principle, and practical applications of resistive touch screens.

Introduction

Resistive touch screens are well-known for their affordability and are widely used in various high-usage applications. This article will explain the structure and working principles of resistive touch screens and how they transmit information to a microprocessor.

Structure of Resistive Touch Panels

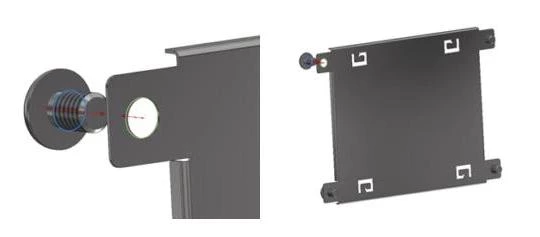

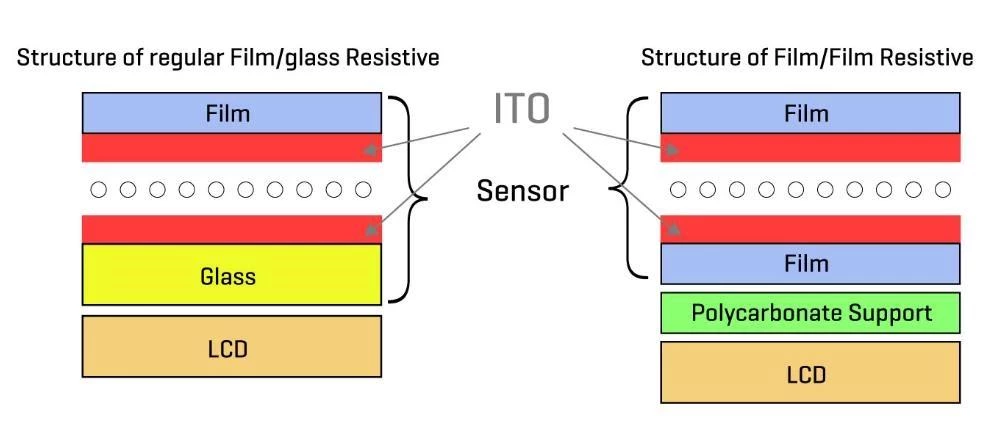

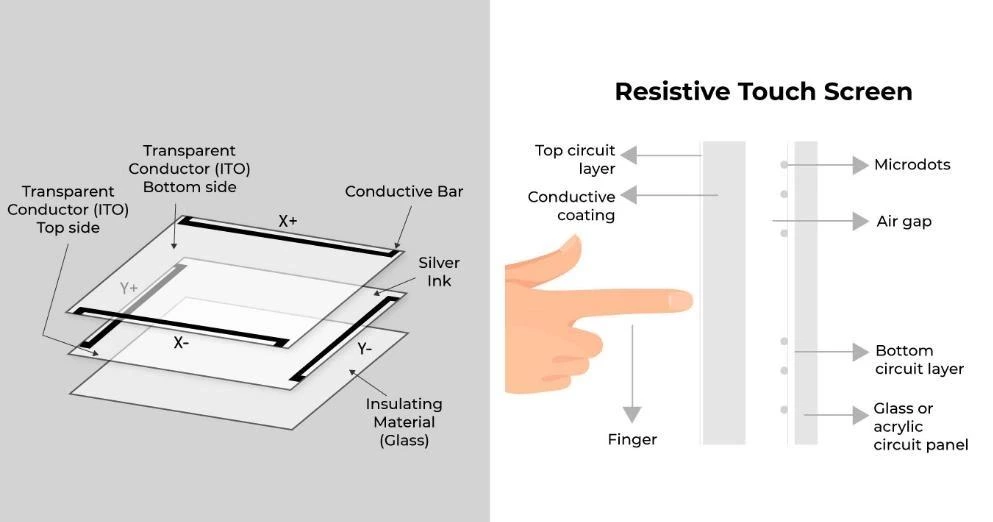

There are two basic structures for modules with resistive touch panels. These structures differ based on the support material used: glass or polycarbonate. The more common structure for resistive touch panels is film/glass. The difference lies in the material of the sensor substrate and the accompanying support. Resistive touch sensors are made of a glass or acrylic substrate, covered with conductive and resistive layers (made of film) and ITO (indium tin oxide). These layers are separated by small spacers.

Working Principle of Resistive Touch Panels

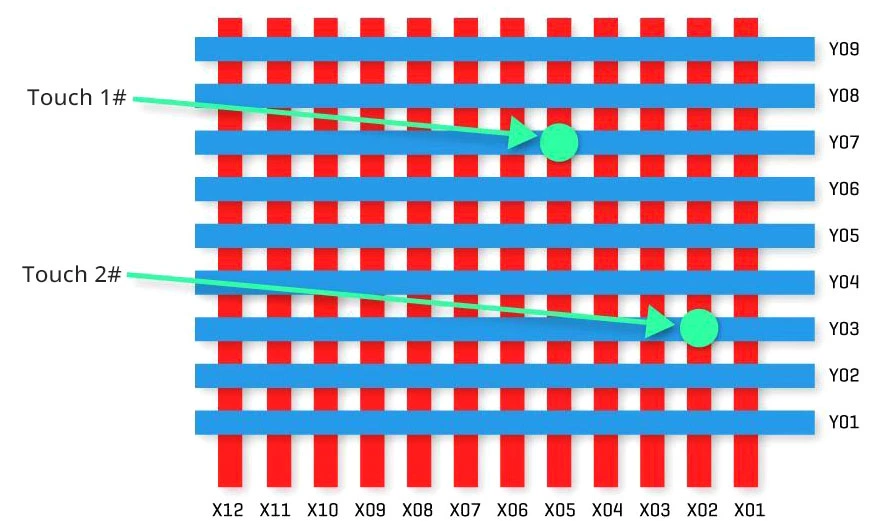

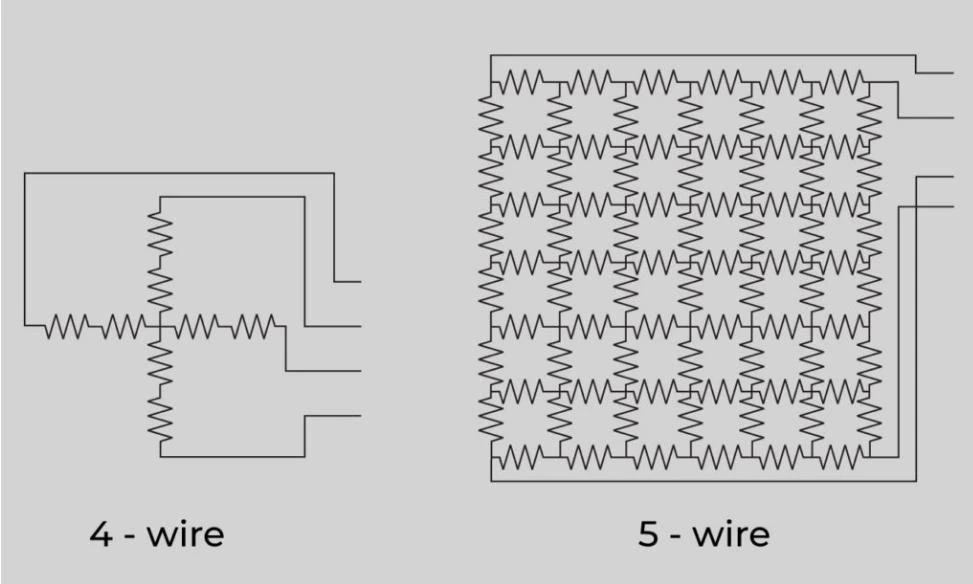

The most common resistive configurations use four-wire or five-wire circuits to determine position coordinates.

Principle diagram of four-wire and five-wire resistive touch panels.

These circuits determine positions in two coordinate dimensions. Since most applications use four-wire technology for resistive touch screens, we will focus on the four-wire solution.

How is the position measured? On the touch screen, voltage is applied in the Y direction. When touched, the layers make contact. At the touchpoint, the voltage can be read from an X electrode, determining the Y coordinate through a voltage divider. Then, with voltage applied in the X direction, the process is repeated, reading the voltage from the Y electrode.

Applications of Resistive Touch Screens

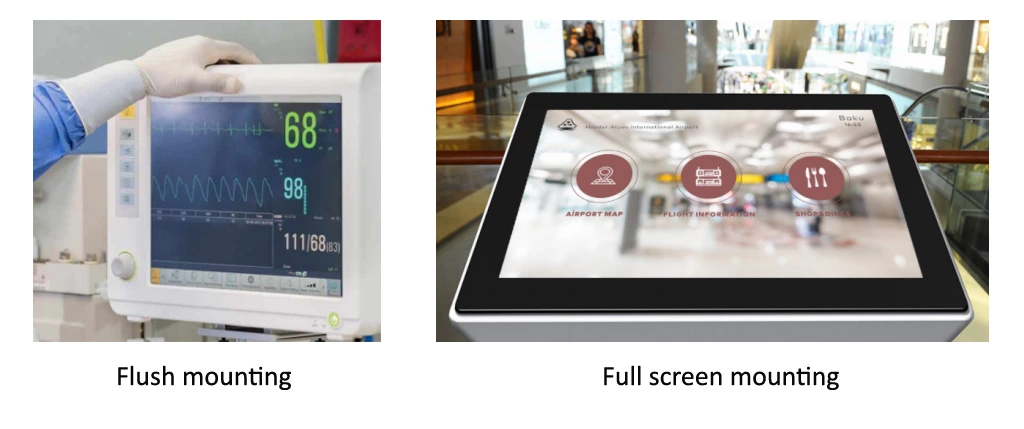

Resistive touch sensors do not rely on the electrical properties of capacitance (in contrast to capacitive touch technology); instead, the sensors respond to pressure on the screen surface. Therefore, resistive touch panels have stronger noise immunity, reducing the likelihood of erroneous operations. Resistive touch technology provides compatibility with non-conductive materials, allowing the use of a stylus and gloves with modules that have resistive touch screens. Resistive touch screens are widely used in applications under harsh environments. Unlike capacitive technology, resistive technology only supports "single touch".