Structure and Working Principle of Capacitive Touchscreens

Capacitive touchscreens are widely popular, but do you know how they work and what they consist of? Let's delve into the details of their structure, materials, and working principle.

Main Components of Capacitive Touchscreens

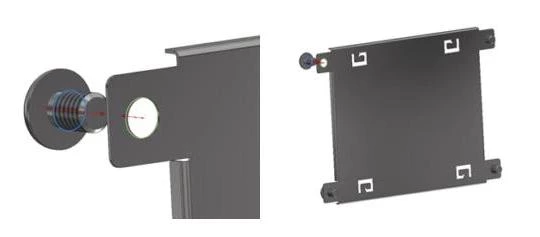

The primary components of a capacitive touchscreen are the cover glass, touch sensor, and touch control board.

Cover Glass of Capacitive Touchscreen

The cover glass of a capacitive touchscreen, also known as the "glass cover," serves as mechanical protection and a decorative element for the entire module. It can be made of glass or synthetic materials, with PMMA and polycarbonate being popular synthetic options. Glass cover materials typically include chemically strengthened glass and thermally strengthened glass. The thickness of cover glass usually ranges from 0.55 to 1.8 millimeters.

A common characteristic of glass is its greenish tint due to iron oxides, especially noticeable at the edges. This effect can be mitigated by using ultra-clear glass to maintain true colors.

Regarding safety, glass is strengthened through post-production processes. Chemically strengthened glass is preferred for thicknesses under 3 millimeters, while thermally strengthened glass is used for thicknesses over 3 millimeters. Thermally treated glass is considered safer. The final step in ensuring safety involves edge finishing with a C-cut to protect against chipping.

CTP Touch Sensor

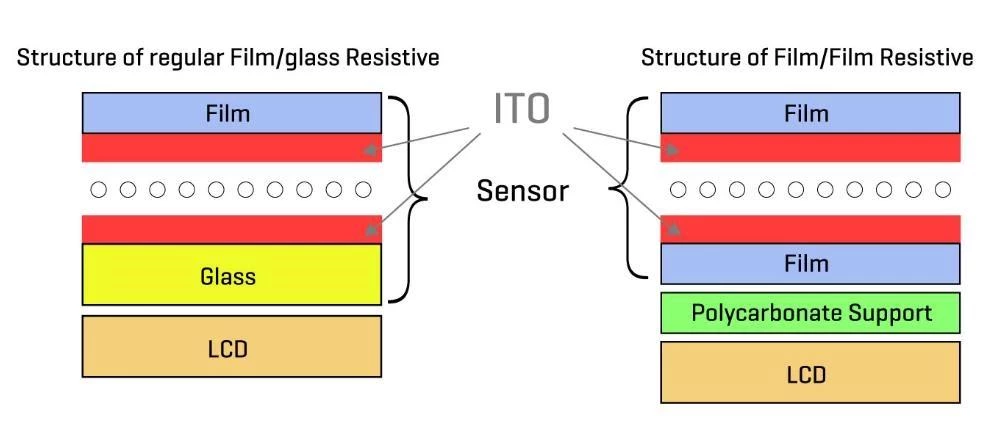

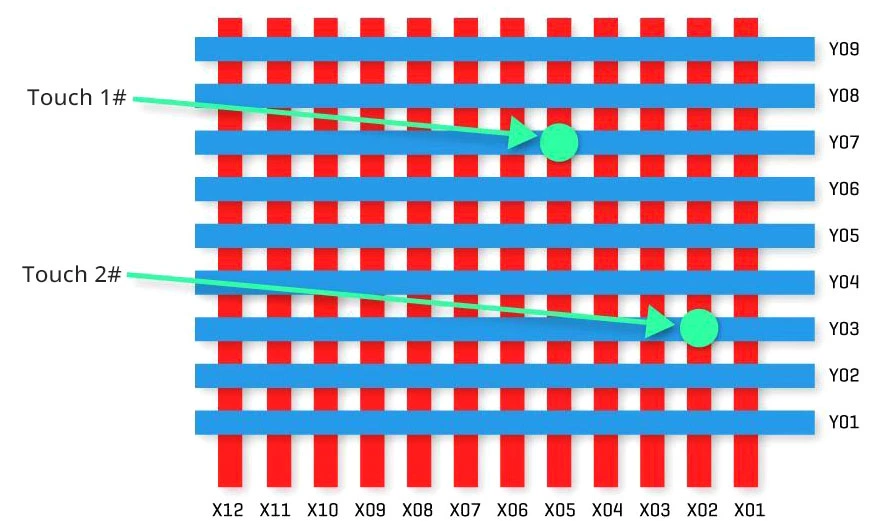

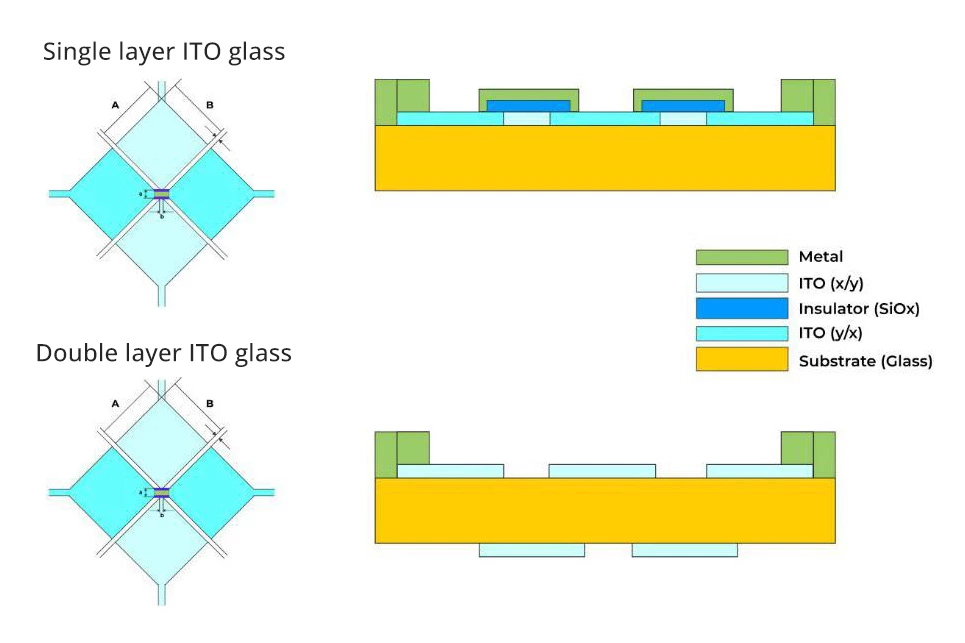

The capacitive touch sensor of a touchscreen consists of two dielectric layers separated by ITO (Indium Tin Oxide) coatings. These layers are arranged in vertical and horizontal rows, forming a matrix. Touch detection is achieved by scanning each axis to identify lines with high capacitance. The intersection of these lines determines the touch location. Typically, the touch sensor is made from double-sided ITO glass, with the sensor patterns created through an etching process.

Additionally, there is a technique to create touch sensors using single-layer ITO glass (SITO). This is done by etching the sensor pattern on one side and bonding specific X or Y electrodes, as illustrated in the following diagram.

CTP Touch Controller Board

The touch sensor ends in electrodes, and a touch controller board is required to collect and manage the data from these electrodes. The selection of the touch controller board for a capacitive touchscreen should align with the module's application and environment, considering several factors.

The first step is communication, where the touch controller board interface needs to be set up, with SPI and I2C being the most popular interfaces. Next, size, efficiency, and safety of the touch controller board should be considered, along with electromagnetic compatibility, including electrostatic discharge and radiation sensitivity. The controller IC can perform various functions to meet product application requirements, including those suitable for waterproof or saline environments, and support for glove operation and special gestures.

In summary, we have analyzed the materials, structure, and working principles of capacitive touchscreens from three aspects: the glass cover, the touch sensor, and the touch controller board.