Mechanical Design of TFT LCD Display Modules

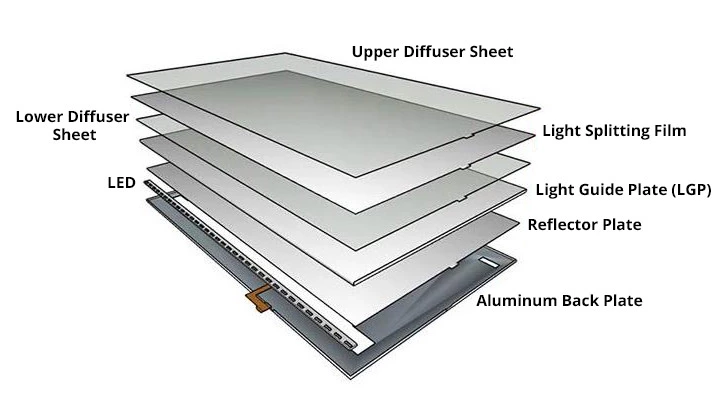

Composition of LCD Screen Structure

TFT LCD display modules must ensure a certain level of strength, which involves material mechanics. Proper heat dissipation during operation, when heat is generated, is related to thermodynamics. Ensuring module quality and yield, and preventing dust from entering the display area, is related to fluid dynamics. This article introduces the mechanical design of TFT LCD display modules from three aspects: strength design, heat dissipation design, and reinforcement design.

1. Strength Design

When designing the structure of an LCD display module, it is essential to meet the vibration and shock resistance specifications of the product. Vibration and shock tests are conducted to analyze the areas of failure, investigate the causes of failure, and then make design changes based on the findings. To minimize design errors, potential causes of failure can be predicted based on past experience, and reinforcement measures can be implemented during the design phase to address potential issues before they occur.

There are two main reinforcement strategies:

-

Interlocking Design: To increase the overall rigidity of the LCD display module, all components must be tightly interlocked. During the design phase, efforts should be made to ensure that the structural components around the module are interlocked in various ways. At a minimum, the front frame and rear panel of the LCD module should be tightly interlocked to securely encase the materials between them. Common interlocking reinforcement methods include screws, snap-fit designs, and adhesive tape.

-

Reinforcement Design: Weak areas in the LCD module structure require additional reinforcement. Common reinforcement techniques include stretching, strengthening ribs, folding edges, and triangular reinforcements.

2. Heat Dissipation Design

LCD display modules generate significant heat after extended operation, and inadequate heat dissipation can lead to a decline in quality and lifespan. Part of the energy from the light source is released as heat, and as the light source’s power increases, effective heat dissipation becomes even more critical. The three basic forms of heat dissipation are conduction, convection, and radiation. When designing heat dissipation, it is important to select appropriate component materials to efficiently diffuse the heat generated by various sources.

From a heat dissipation perspective, metals are the best choice, as they can dissipate heat quickly. Among metals, aluminum alloys with magnesium content have excellent thermal conductivity. When designing heat dissipation, it is necessary to identify potential issues that may arise due to heat exposure in the components. The backlight source, in particular, has strict thermal reliability requirements. Overheating of the backlight can affect circuit components' performance, reduce the luminous efficiency of the light-emitting elements, cause wrinkles in optical films, and create uneven backlight display effects. In some cases, this can lead to instability in the liquid crystal display during module aging. A fundamental strategy for backlight heat dissipation design is to improve the luminous efficiency of the LED light sources. The higher the LED efficiency, the less heat is generated. Currently, the power drive efficiency of LED lights typically reaches around 99%, resulting in minimal heat generation.

3. Dust Protection Design

During transportation or use at the client’s site, dust and other foreign particles entering the module can cause display issues. The key countermeasure for dust protection is to use a sealed structure. Once dust enters the module, the most easily visible areas under illumination are the back of the display screen, the surface of the optical films, or between optical films. These areas are most susceptible to dust, which can negatively affect display quality. LCD module products typically undergo dust evaluation tests in a dust chamber, and the results must ensure that no dust enters the module.

In conclusion, this article has briefly introduced the key mechanical design considerations for TFT LCD display modules, focusing on strength design, heat dissipation design, and reinforcement design. We hope this information will be helpful.