Analysis of LCD Screen Reinforcement Techniques

LCD screens are widely used, especially in industrial and outdoor settings. However, harsh outdoor conditions—like extreme temperatures, humidity, vibration, shock, and electromagnetic interference—can damage the internal structure and backlight of an LCD, compromising its display stability and longevity. To make LCD screens better suited for these environments, reinforcement techniques are essential. These techniques involve structural, electrical, and systemic adjustments to maintain stable performance in adverse conditions.

1. Temperature Impact

-

Challenges: Industrial LCD screens typically operate between -20°C and 70°C. Both extreme heat and cold can impact the liquid crystal materials and backlight, potentially slowing response times and reducing backlight brightness and lifespan.

-

Solutions: For low temperatures, thermal design techniques include using wide-temperature LCD technology or integrating an ITO heating glass layer to warm the module. At high temperatures, cooling measures like heat sinks or liquid cooling are used to regulate temperature.

2. Vibration and Shock

-

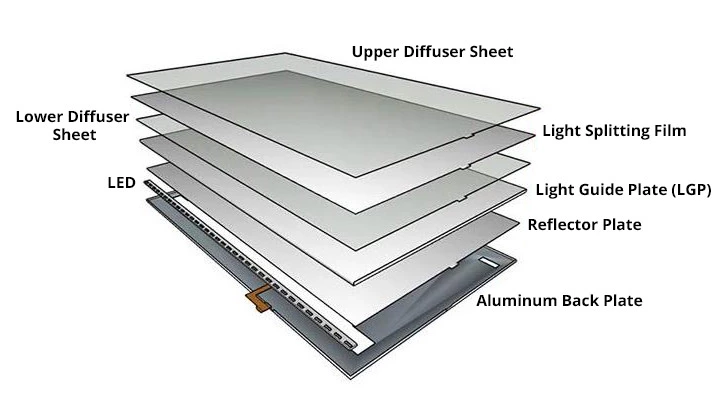

Challenges: In harsh settings, vibrations and shocks can affect the LCD’s thin layers, backlight, electrical components, and flexible circuit boards, leading to misalignment, fractures, or breaks.

-

Solutions: Using stronger external casings and tempered glass covers can increase durability. Extra brackets in the backlight assembly and silicone encapsulation for electrical components can further reinforce the structure.

3. Humidity and Dust

-

Challenges: Moisture and dust can enter LCD screens, causing corrosion, blocked heat dissipation, and display issues.

-

Solutions: A sealed LCD design with rubber strips under the glass cover and welded casing helps protect against water and dust infiltration.

4. Electromagnetic Interference (EMI)

-

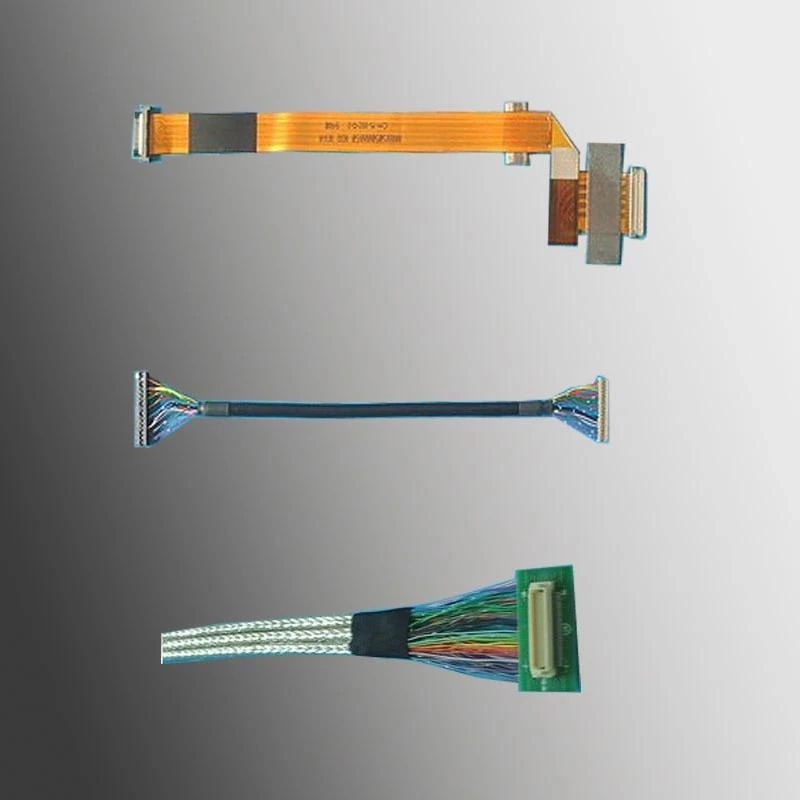

Challenges: Industrial and outdoor environments often have strong electromagnetic interference, which can affect the stability of LCD display transmission.

-

Solutions: Anti-EMI design, including shielded cables, filters, ferrite rings, and rubber strips, reduces EMI effects, supporting stable display performance.

Temperature regulation is crucial to maintaining optimal display quality under extreme conditions, highlighting the importance of advanced reinforcement techniques in LCD screen design. For more on LCD screen options and wide-temperature displays, visit Disea Electronics: