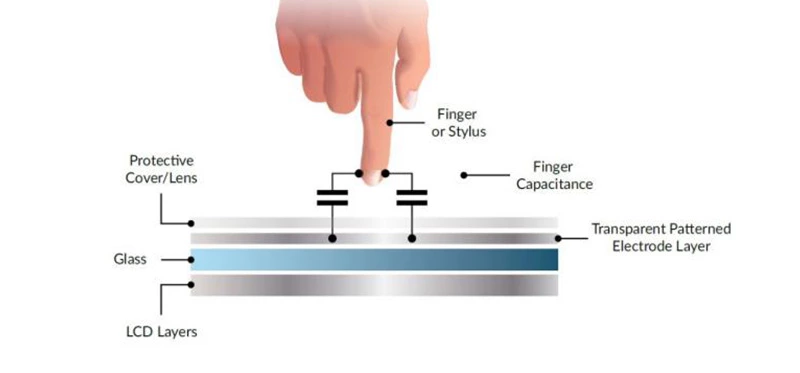

Capacitive touch screens are currently the most popular products in the display industry and are widely used in mobile phones and tablet PCs. The ability to scroll, zoom and pinch is an experience that cannot be matched by resistive capacitive screens.

Capacitive touchscreens have also come a long way in industrial displays in recent years, but unlike consumer products, industrial products are used in a much wider and harsher environment. The performance of capacitive screens is put to the test.

Disea designs and manufactures capacitive screens with a G+G structure, which is more stable and better suited to industrial displays.

Therefore, our cover lens is usually glass. To find out more about cover lenses, click here.

This is critical to the functionality you want to achieve with a capacitive screen. Typically, consumer capacitive touch controllers have a short lifecycle, they are highly biased and often cost optimised, and as market demand changes, these capacitive touch controllers may have to be redesigned or discontinued and their lifecycle may be only 2-3 years. In contrast, industrial capacitive touch controllers are more concerned with robust performance and longevity. This means that a particular driver IC can be available for up to 10 years or more without any changes. This is what industrial displays demand and what you want. Once developed, your product will not require any future changes.

Anti-interference: capacitive screen is the use of capacitance value changes to achieve the capture of the coordinates, the capacitance value is very important, but it is very easy to be caused by a number of interferences, such as AC power supply, frequency motor, GSM antenna, induction chip, stray power signal, they will lead to inaccuracy of the coupling capacitance of RX TX, and ultimately touch the position is not correct, touch unresponsive, automatic triggering and other undesirable situations. Then touch driver IC itself if owned powerful anti-interference ability is particularly important.

| ITEM | Description | Value |

|---|---|---|

| IEC CI/CS test classes | Conduction test, standard classes 1-3 | 1V, 3V, 10V |

| ESD test level | Air discharge/contact discharge | Air ±15KV Contact ±8KV |

| EMI test level | EMI peak level,average level | Class A/Class B/Class C |

Capacitive touch controllers typically have I2C and USB interfaces for communication. We can also provide you with both interfaces in the same product. Where USB can be directly adapted to Windows and Linux systems, this saves a lot of development time.

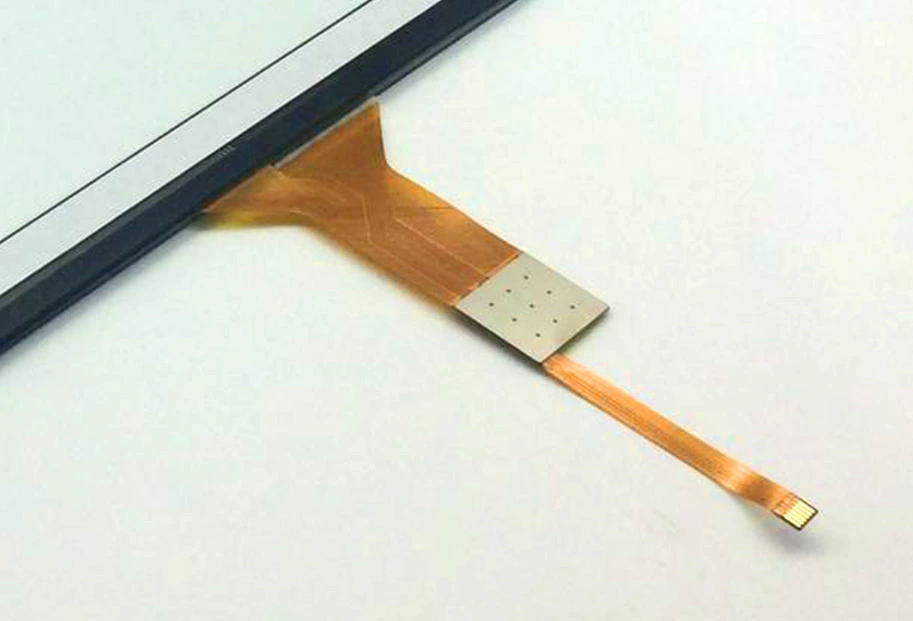

FPC with I2C interface detail

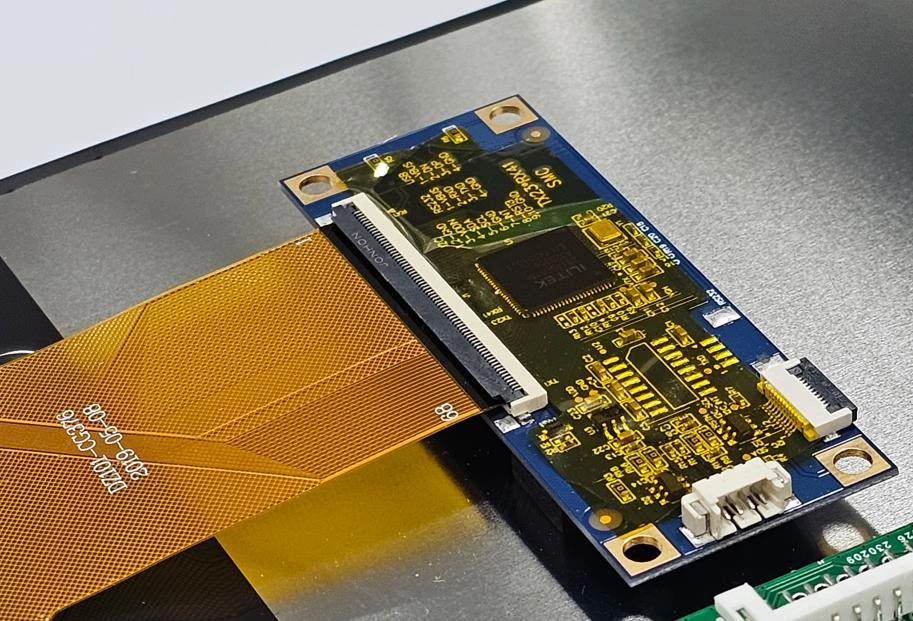

PCB with I2C &USB interface detail

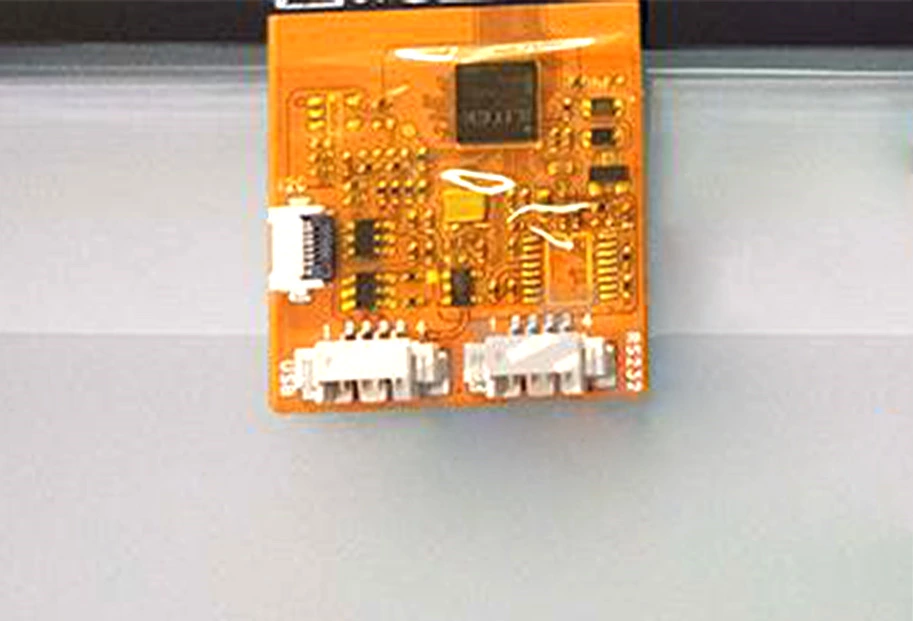

FPC with I2C &USB interface detail

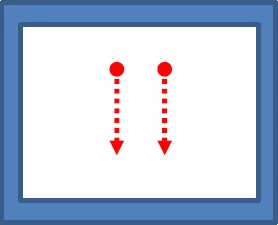

Liquids or conductive materials can affect mutual capacitance signal and make touch performance unstable.

Below describes how the touch performance being affected by water for a projected capacitive (PCAP) touch system.

| NO. | Condition | Touch Performance |

|---|---|---|

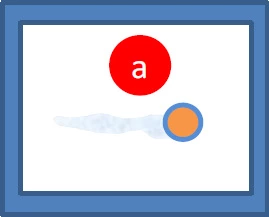

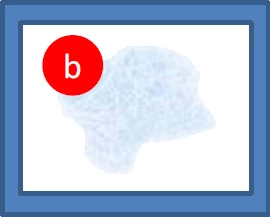

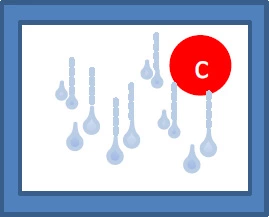

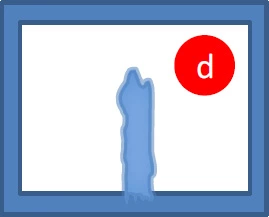

| a | Wet Finger | Few jitter or not accurate influences on sensitivity and linearity. |

| b | Sprayed / Moisture | Some jitter or not accurate influences on sensitivity and linearity. |

| c | Water Drips | Running water drips might cause a false touch. There might be a false touch,break or jitter when drawing across water drips. |

| d | Pouring | Pouring may cause a false touch. There may be some false touches, breaks or jitters when drawing across pouring water. |

| e | Puddles | Puddles would cause a false touch. There may be some obvious false touches, breaks or jitters in the trace when drawing across puddles. |

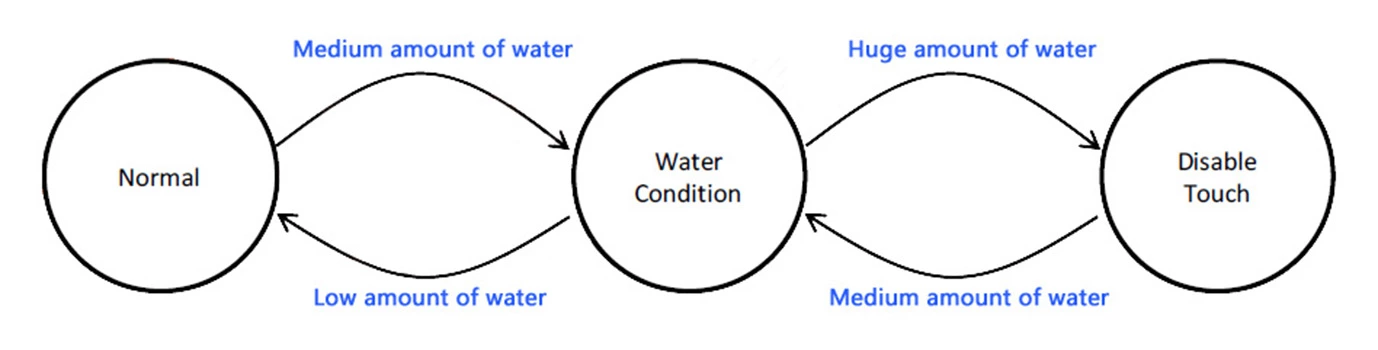

The water resistance function in EETI EXC80H/EXC82H touch solution is designed to against water interference. Touch controller will detect the water situation on the touch panel and enable water resistance mode, or disable touch function. Below state diagram shows the mode switch for water resistance.

Touch function will be downgrade under water condition mode, it changes to single touch with two finger gesture to maximize the stability of touch performance under water interfering. The firmware can also be fixed in the water condition mode if required, which makes most stable touch function for water proof orientated applications.

The followings are the water resistance criteria after applying water resistance function when simulating the water condition on the touch system tilted to proper angle (e.g., 60° degrees)

Water Resistance Performance Table

| Fresh Water | 5% Salt Water | ||||||

|---|---|---|---|---|---|---|---|

| No. | Water behavior | False Touch | Single Touch | Two Finger Gesture | False Touch | Single Touch | Two Finger Gesture |

| 1 | Wet finger | No False Touch | Normal | Normal | No False Touch | Normal | Normal |

| 2 | Spray/ Moisture | Low Risk | Normal | Normal | Low Risk | Low Impact | Low Impact |

| 3 | Water Drips | Low Risk | Low Impact | Low Impact | Medium Risk | Medium Impact | Medium Impact |

| 4 | Pouring | Medium Risk | Medium Impact | High Impact | High Risk | High Impact | N/A |

| 5 | Puddles | High Risk | High Impact | High Impact | High Risk | High Impact | N/A |

| 6 | Wipe out water | No False Touch* | Normal | Normal | No False Touch* | Normal | Normal |

| False Touch | Description |

|---|---|

| Low Risk | Rarely a false touch near the border. |

| Medium Risk | Occasionally a false touch near the border. |

| High Risk | Often a false touch near the border. |

| Wipe out | The contact of wiping may cause a touch. No false touches after wiping out the water. |

| Touch Performance | Description |

|---|---|

| Normal | No obvious performance drop. |

| Low Impact | Rarely broken line or jittered drawing. |

| Medium Impact | Occasionally broken line or jittered drawing. |

| High Impact | Often broken line or jittered drawing. |

| N/A | Very poor performance and not suitable for touch operation. |

Note: Salt water or other liquid with high conductivity will cause serious signal interference and make touch unstable. Besides, the water resistance performance is related to the touch sensitivity. If customers want to apply high sensitivity for glove touch, that will cause poor performance of water resistance.

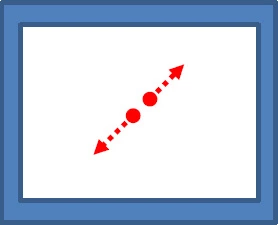

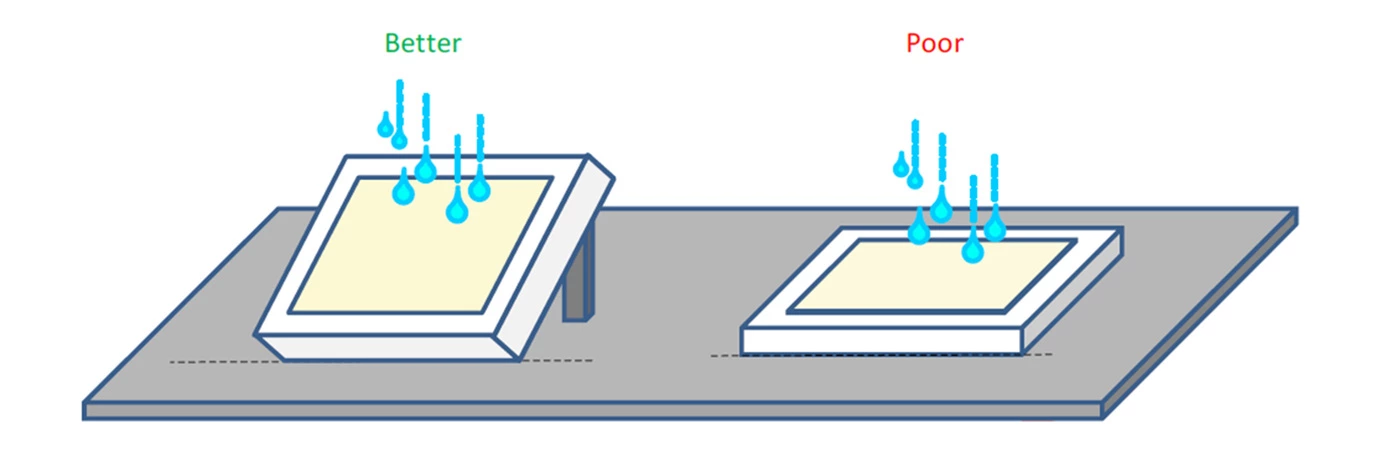

The followings are the better designs for good water resistance performance:

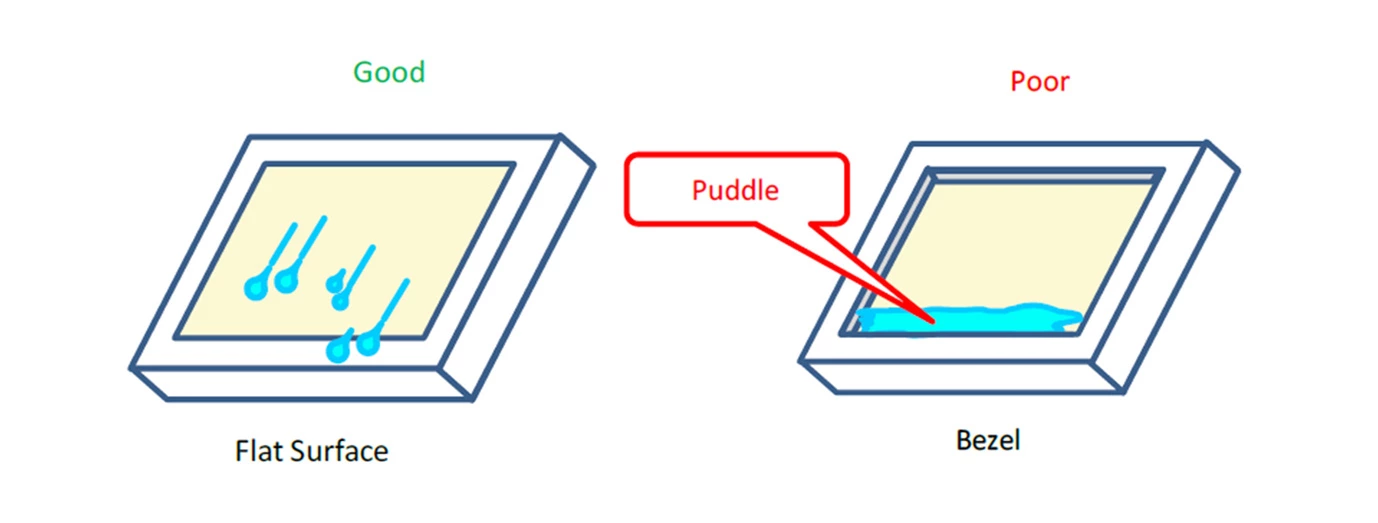

a. System should be a flat surface design and able to drain water off easily.

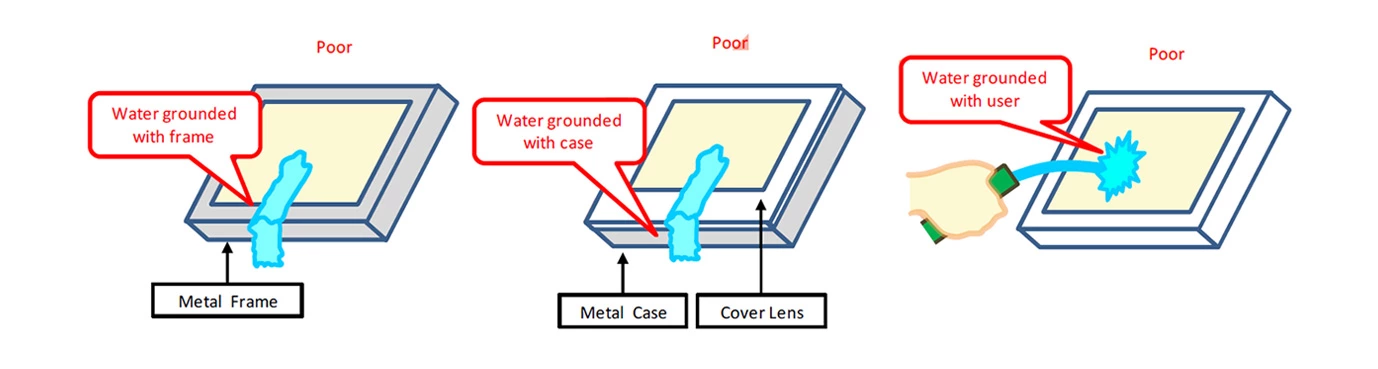

b. The border around touch sensor should not be conductive. Water will be grounded to the system through the metal border. The water signal is similar to a real touch. If water connects users and touch panel, it is similar to a finger touch, too.

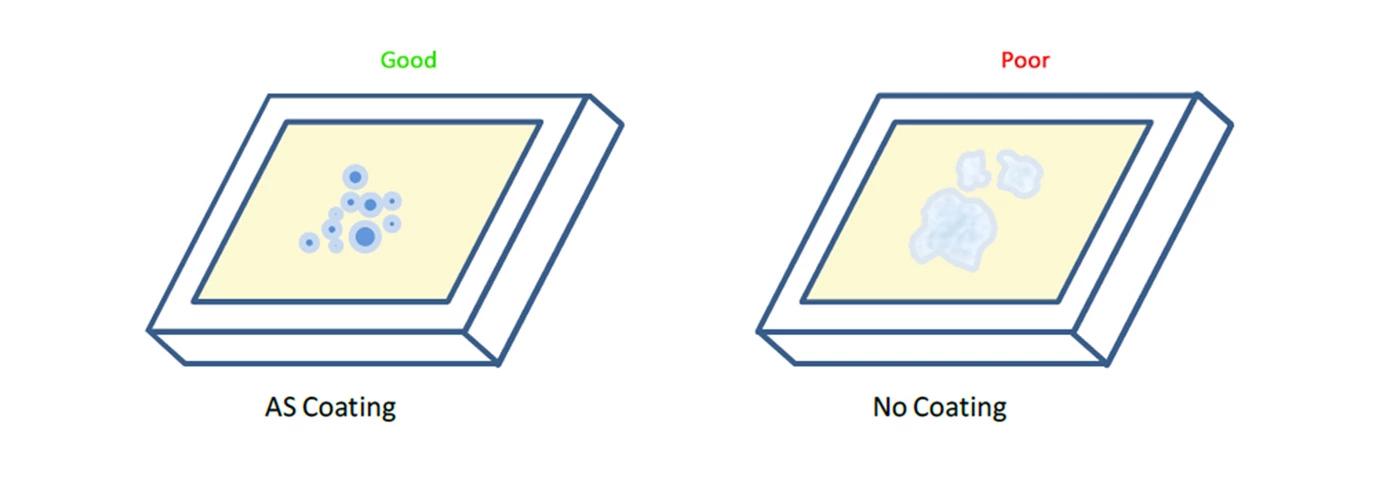

c. Water repellent coating (AS coating) on the cover glass can make great help to decrease water contact area, which reduces the water interference signal strength.

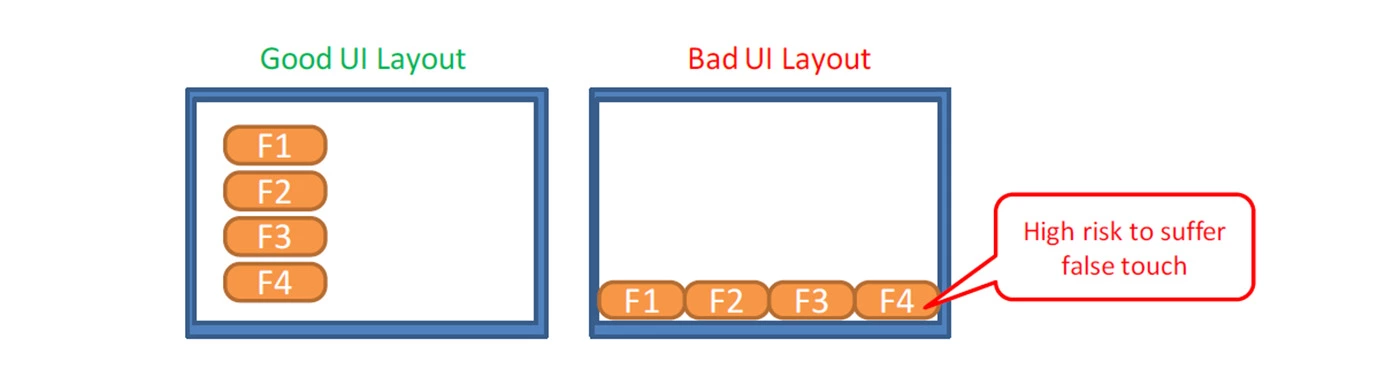

d. A proper UI design can help reduce the risk of abnormal operation, since the water is more easily to have false touches on the edge area. Please avoid designing UI functions around the edge area.

Industrial displays are used in harsh environments, sometimes requiring workers to wear gloves, so it is important that capacitive displays support glove mode. There are many different types of gloves, from simple ones such as medical latex gloves to thicker rubber and cotton gloves, and we will adapt reliable software for use in time. Sometimes there is water mist, water droplets etc on the surface and such applications can be handled perfectly.

For glove touch fine-tune, the fine-tune process is the same as the finger s. Generally, the touch with glove will generate small touch signal. The key point to support glove touch is to raise the sensitivity, i.e.. Reduce touch thresholds. However, the high sensitivity also means the low reliability and stability. There will be more risks against environmental variances, ghost touch, water resistance ,etc. For a reliable and stable touch performance, EETI suggest the touch % > 5 and SNR >= 5 in the required input condition if possible. Also, the [EnableThickCoverLens] function may help improve touch performance under glove touch. The followings are the sample gloves and specification for reference. (ITO pitch: 4.5 mm ~ 5.0 mm)

| Thickness: 0.25 mm |

| Material: Nylon |

| Cover glass limitation: < 6.0 mm |

| Thickness: 0.3 mm |

| Material: Rubber |

| Cover glass limitation: < 6.0 mm |

| Thickness: 1.0 mm |

| Material: Leather |

| Cover glass limitation: < 3.0 mm |

| Thickness: 1.0 mm |

| Material: Synthetic leather |

| Cover glass limitation: < 3.0 mm |

| Thickness: 1.5 mm |

| Material: Leather |

| Cover glass limitation: < 2.0 mm |

| Thickness: 1.5 mm |

| Material: Synthetic leather |

| Cover glass limitation: < 2.0 mm |

| Thickness: 1.8 mm |

| Material: Cotton |

| Not recommend |

| Thickness: 2.0 mm |

| Material: Suede |

| Not recommend |

70+ engineers work for DISEA, most of them are from industry leaders of TFT LCD module, such as Tianma, BOE-Varitronix, etc. Each of our Core Team Members has 15 years of industry experience.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.